At GROEBNER, we are a strategic sourcing partner with decades of knowledge, aiming to be more than a company that simply fills product orders. We guide natural gas companies on which products will be the best investment for years to come. Read how one of our customers gained operational efficiency within their utilities by standardizing their AMI (Advanced Meter Infrastructure) system.

Challenge:

A Midwest city was running dual meter reading systems, with the water department using the Sensus FlexNet AMI (Advanced Meter Infrastructure) system and the gas and electric departments using a different brand of AMR (Automated Meter Reading) system. This setup required different procedures and software for data collection from the two types of systems. That meant higher costs for man-hours and internal office infrastructure. It also meant that the gas and electric departments did not enjoy the ease of data gathering and remote system management that the water department did.

Solution:

GROEBNER has a strong relationship with the city’s gas utility staff, so we were in an excellent position to help them meet this challenge. Working with staff from all three utilities, we came to understand the specific needs across the whole system network. Through our combined team analysis, GROEBNER recommended a move to the Sensus FlexNet system for all three utilities. Each utility would then have the benefits of additional data, remote function management, and lower system costs.

Our analysis also indicated the utilities could benefit from updating and standardizing all their meters to two offerings from Sensus (down from six different meter types they were using previously). Standardization of the overall FlexNet system and the meters ensures ease of system maintenance, as well as allowing for uniformity of staff training.

Results:

- Collect, manage, and analyze data more frequently, giving utilities and customers the most current system information

- Internal standardization of utilities’ systems, leveraging staff training across the disciplines, and easing system maintenance requirements

- On-demand readings of system data, reducing man-hours and system operation costs

- Remote management of services, allowing for more immediate system updates and upgrades

- Single strategic sourcing for equipment through GROEBNER, ensuring supplier network access and knowledge of ongoing system needs

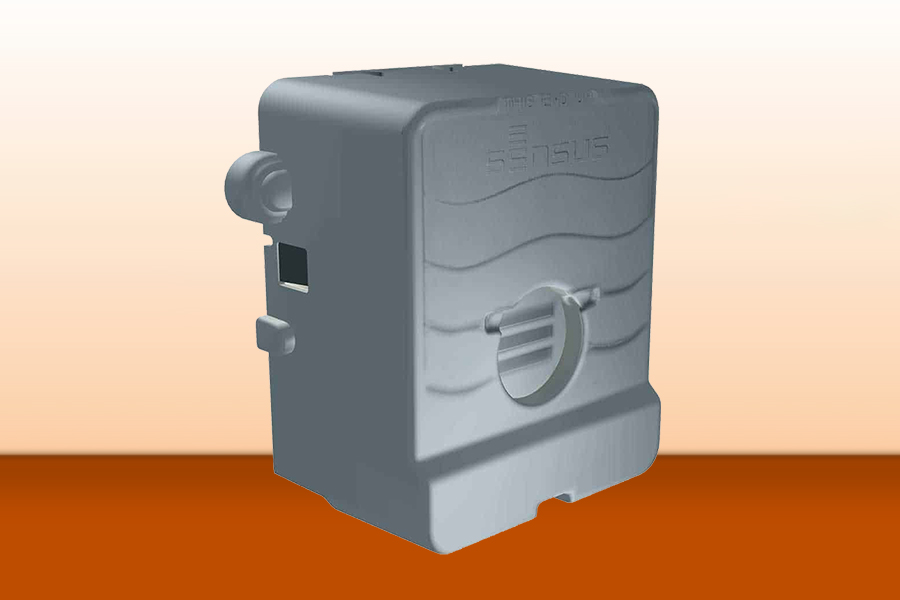

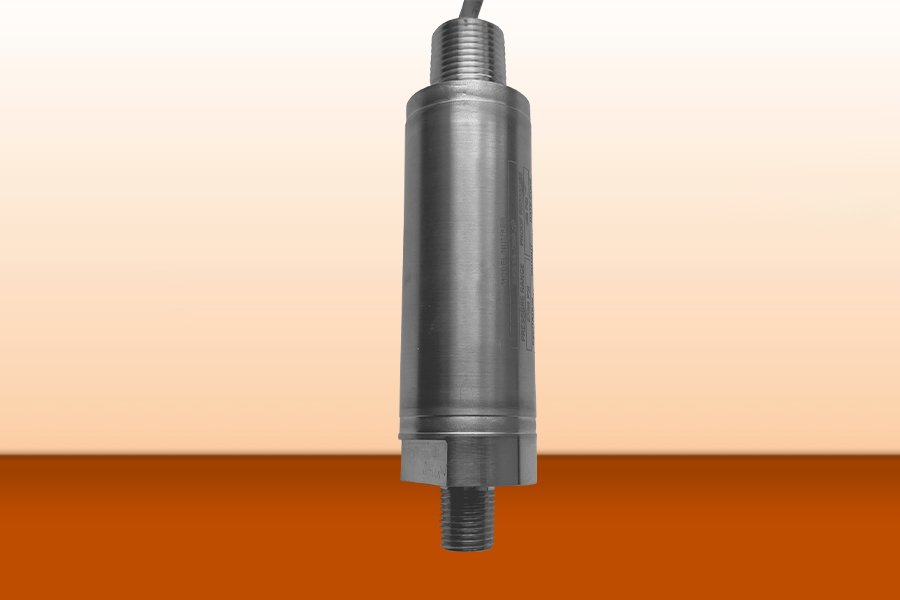

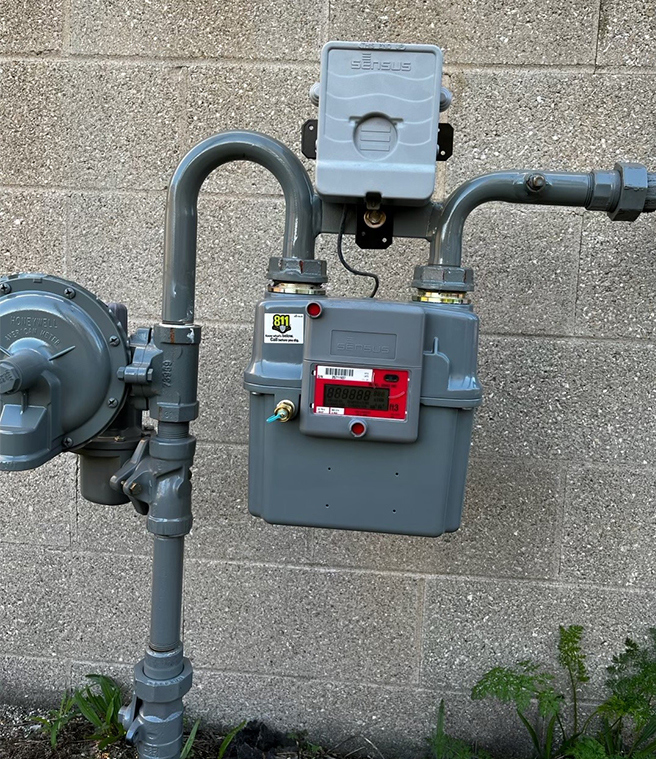

Manifold installation of Sonix IQ 425 CFH meters with integrated FlexNet radios. |  Dual pressure monitor application with SmartGateway and two Barksdale Pressure Transmitters. |